Stingray Bass Build – Custom Hybrid Bass by bogoworkshop

This handcrafted Stingray bass build by bogoworkshop showcases the full creation process of a MIDI-compatible instrument — blending traditional tonewood work with modern Roland electronics. We combined CNC precision, hand-wound pickups, and our first stainless steel bridge prototype to produce a unique hybrid bass. Every detail in this Stingray bass build was crafted in-house, with ergonomic comfort, tonal depth, and MIDI control at the core of its design.

🪵 Tonewood Selection & Preparation

We began the Stingray bass build by selecting thick hardwood boards, each at least 50mm, to ensure a resonant and structurally solid bass body. After gluing and flattening, the blank was ready for modeling and shaping. The wood selection process was vital to ensure long-term stability and consistent tonal output. For more insights into tonewood choices, check out The Wood Database.

📐 Body Modeling & Proportion Check

We digitally modeled the Stingray bass build, verifying scale length, pickup locations, and ergonomic contours. Precise measurements were critical to accommodate both analog and MIDI electronics. We ensured bridge alignment, hand comfort, and symmetrical flow through CAD rendering before cutting.

⚙️ CNC Body Cutting & Finishing

This phase of the Stingray bass build combined digital accuracy with tactile craftsmanship. With the CAD files finalized, the CNC machine carved out the body and cavities. We then hand-sanded all edges and curves, enhancing both playability and finish adhesion.

🎨 Painting & Polishing

The body of the Stingray bass build was finished in bold red, sealed in multiple coats of clear lacquer. We polished the surface to a mirror gloss using high-grit wet sanding and buffing techniques. This durable finish both protects the wood and enhances the instrument’s visual impact under stage lights.

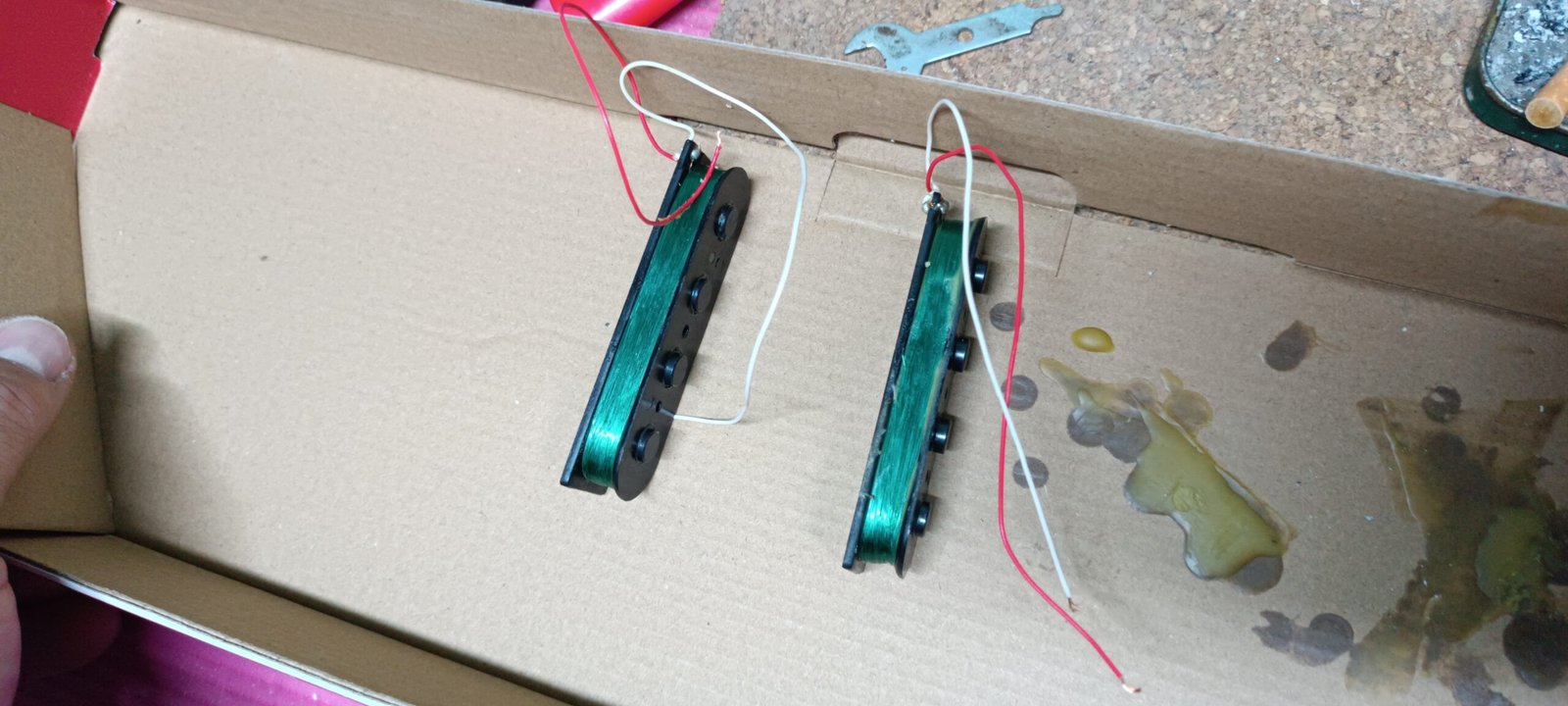

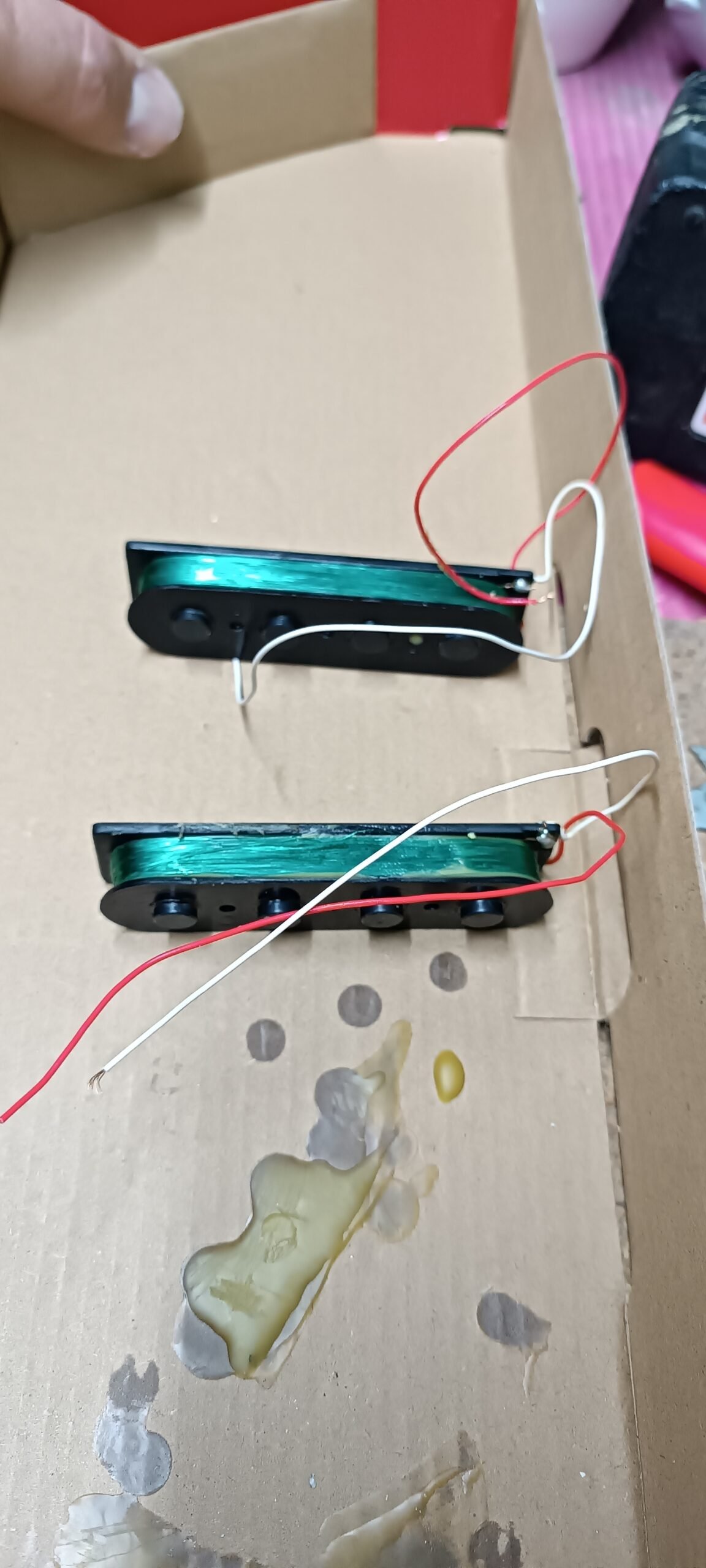

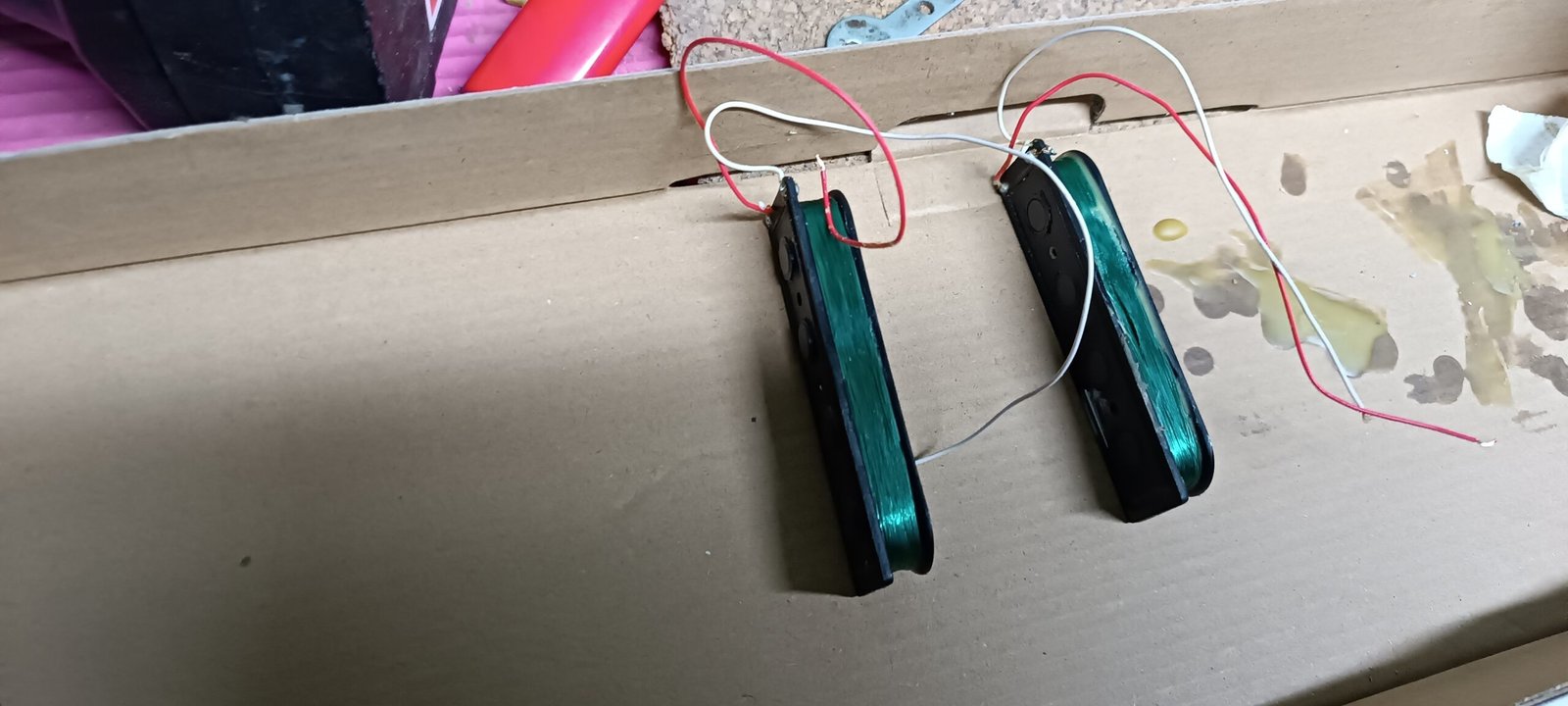

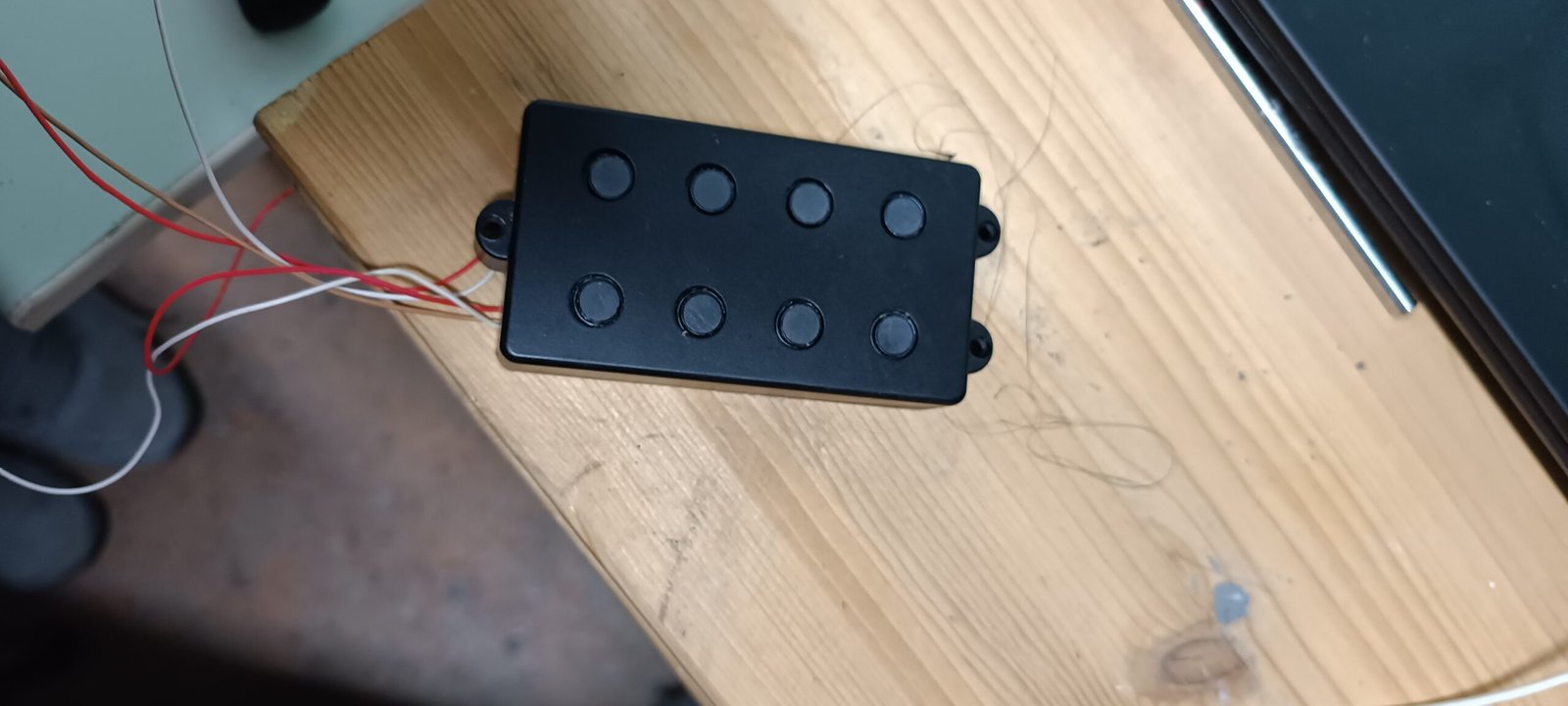

🧲 Hand-Wound Pickups

A critical part of the Stingray bass build was the pickup system. We hand-wound each coil, wax-potted them to reduce microphonics, and tested their impedance and tone. The coils were matched for clarity and punch, especially in the low-mid range where modern players demand response.

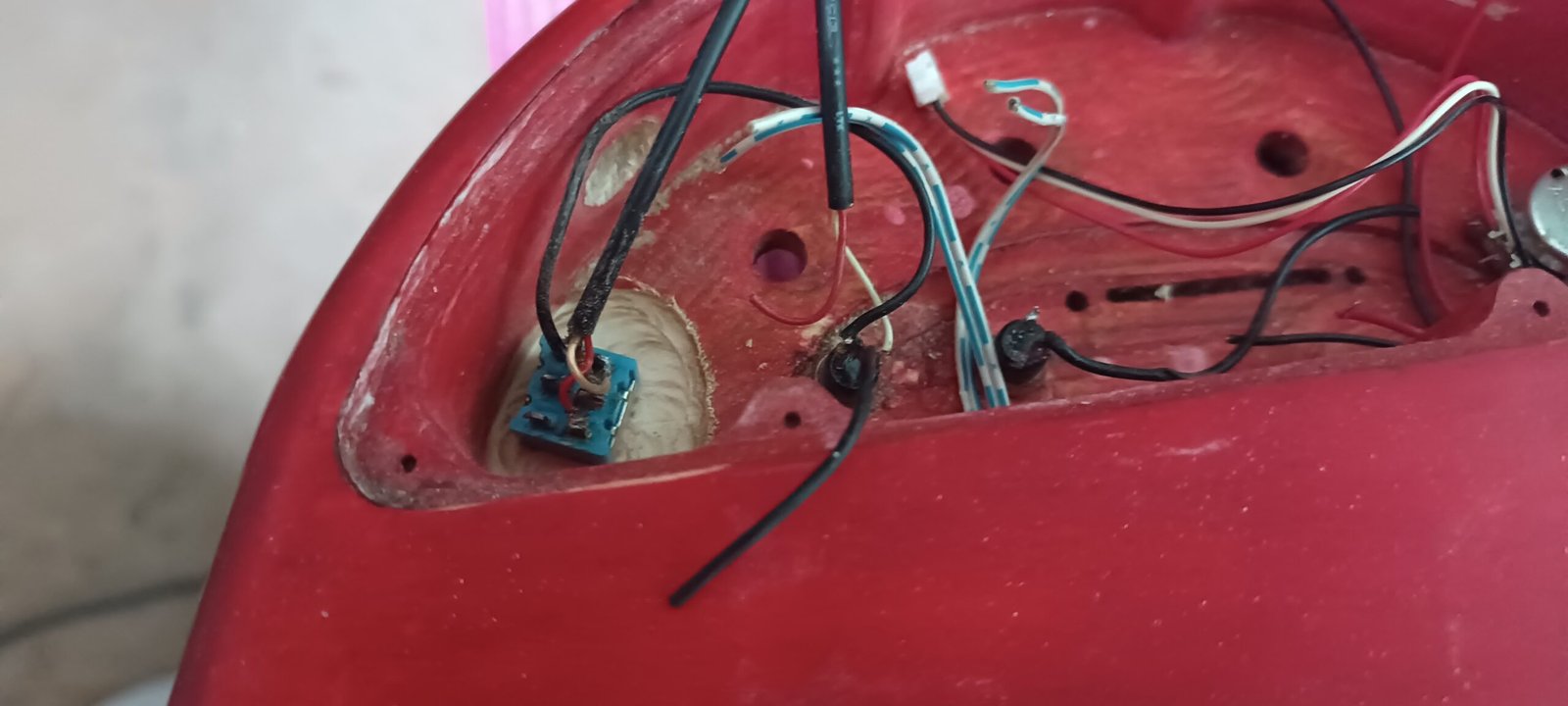

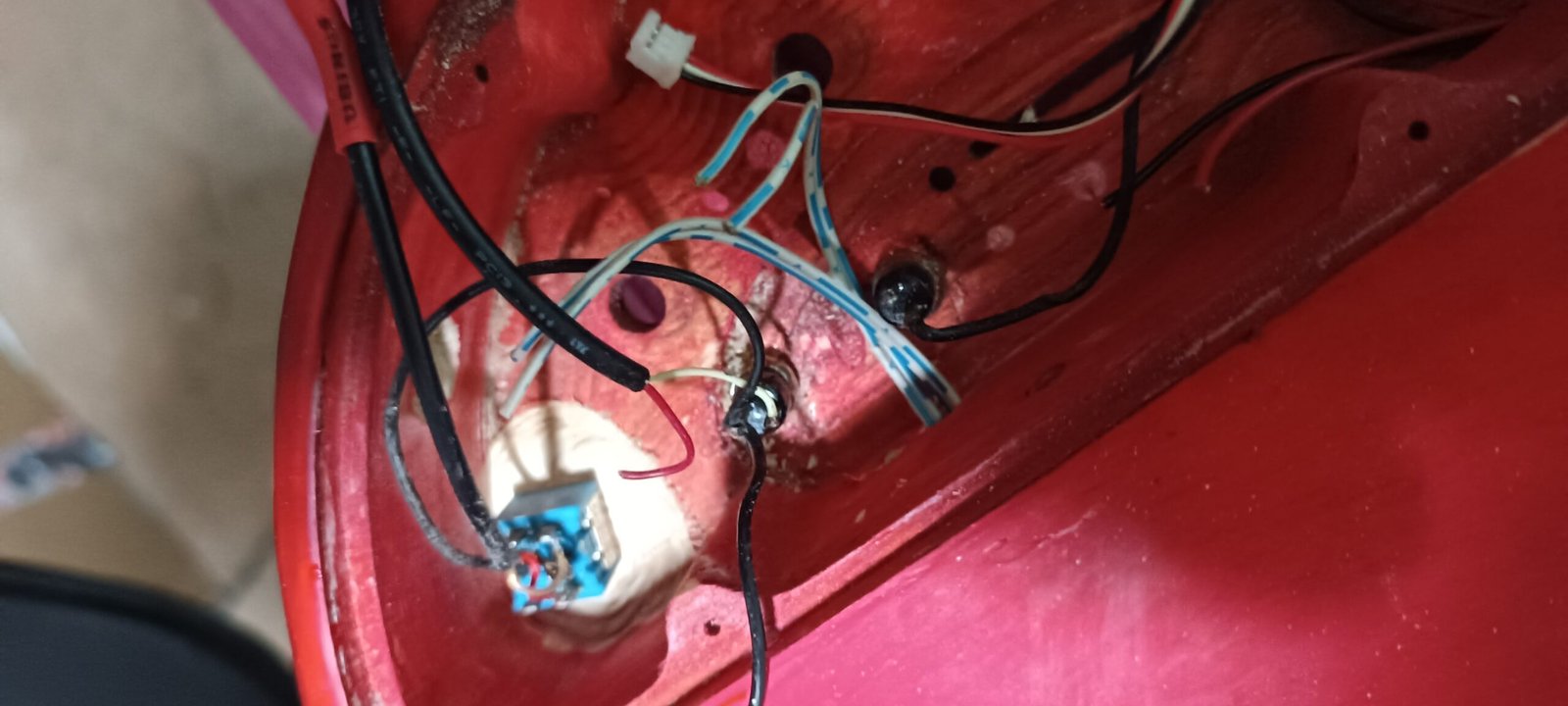

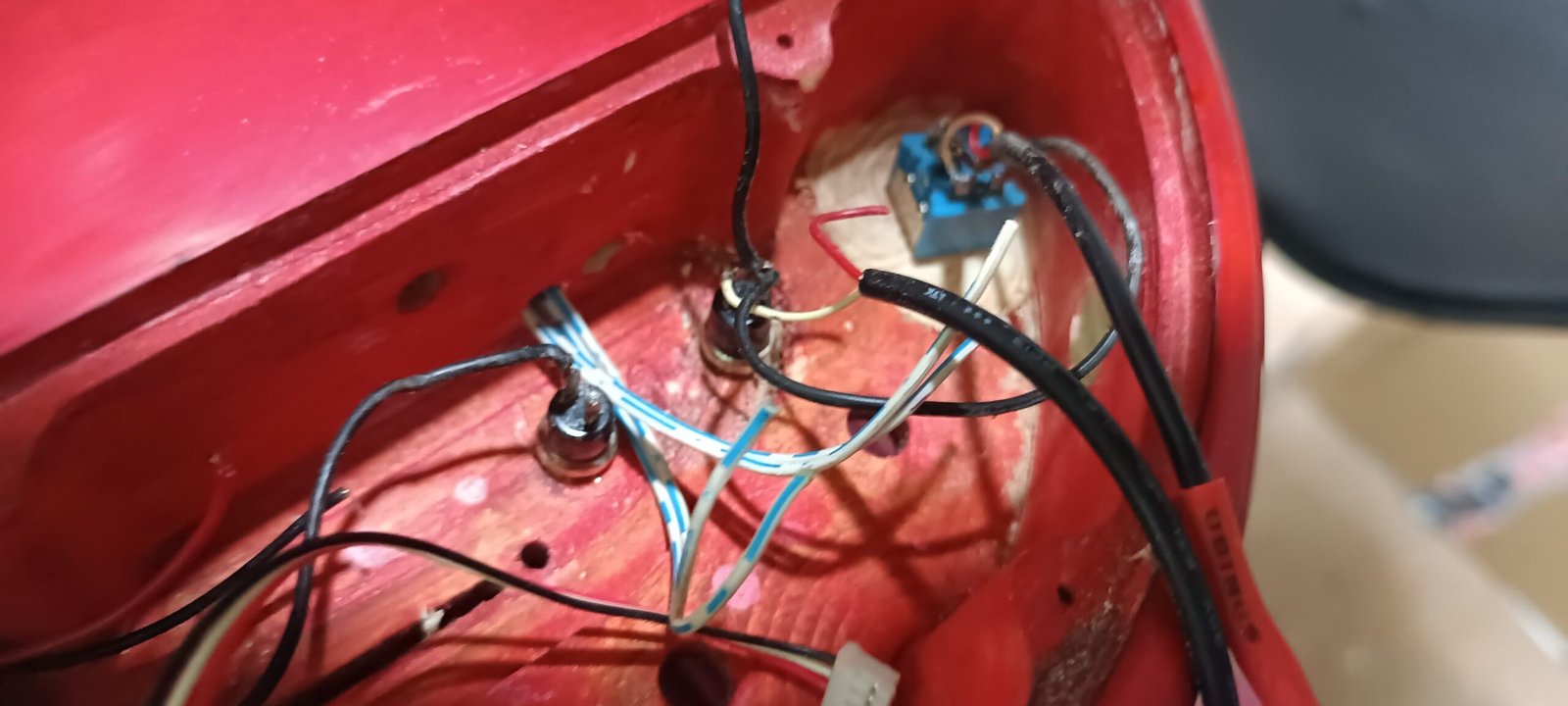

🎛️ Roland GK3 Electronics Integration

This Stingray bass build integrates the Roland GK3 MIDI system for expanded synth and digital output. We routed the body to fit the control board and installed toggles, volume controls, and patch switching buttons. For more about the GK3 system, visit the Roland GK3 official page.

🪗 Neck Installation & String Action

To complete the Stingray bass build, we installed a precision-fit neck and optimized the string action. Fine-tuning the pocket depth and bolt pattern ensured perfect scale alignment. Playability and MIDI tracking were validated after shimming, fretting, and intonation.

🔩 Hardware Installation – Stainless Steel Bridge

One highlight of this Stingray bass build is our custom stainless steel bridge. Cut from 3mm polished steel, this bridge improves resonance, sustain, and tuning stability. It’s a prototype for upcoming bogoworkshop parts and was aligned precisely with the pickup array.

🧪 Electronics Installation & Testing

Final testing on the Stingray bass build included analog and digital signal verification. We calibrated the GR-55 controller, ensured proper shielding, and ran diagnostics on potentiometer ranges. MIDI patching and switch functionality were thoroughly validated.

🎉 Conclusion

This Stingray bass build was a complete fusion of lutherie and electronics — a functional prototype that now inspires future product development at bogoworkshop. Explore our custom bass parts here. From wood to wiring, every step was driven by a desire to build the ultimate hybrid bass for modern players.