Why We Switched to 3D Product Renders – A Smarter Visual Upgrade at bogoworkshop

At bogoworkshop, we’ve always been focused on detail. Every bridge, thumb rest, or accessory we make for violin, cello, and bass is crafted with care. But one thing was slowing us down: product photography.

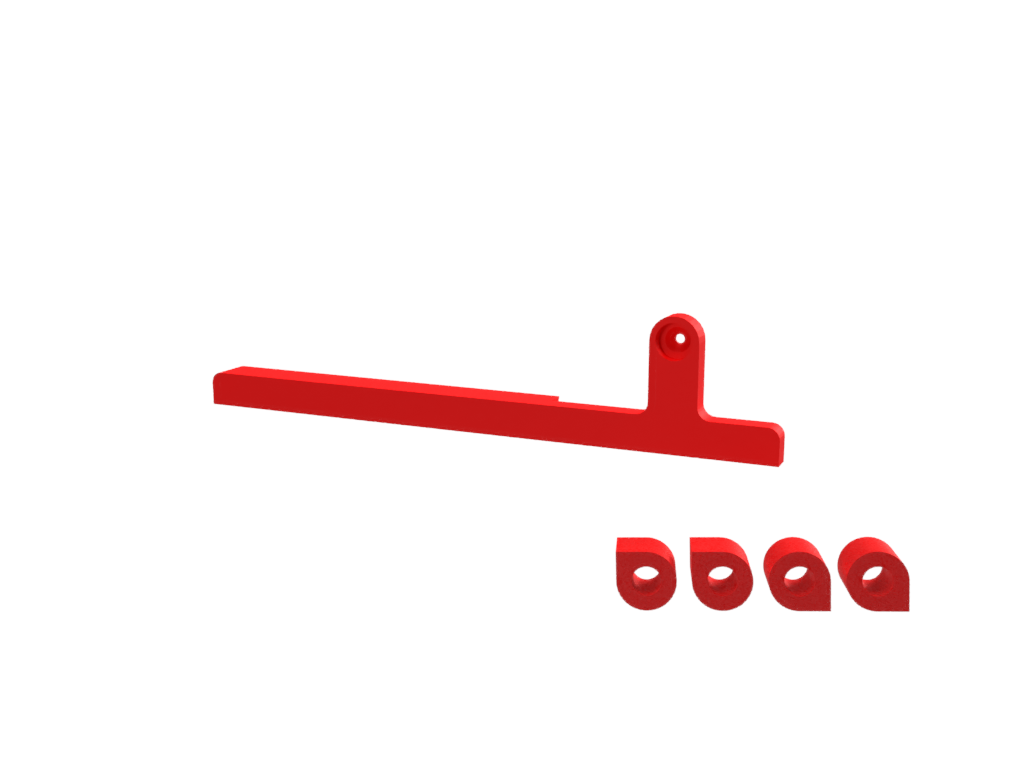

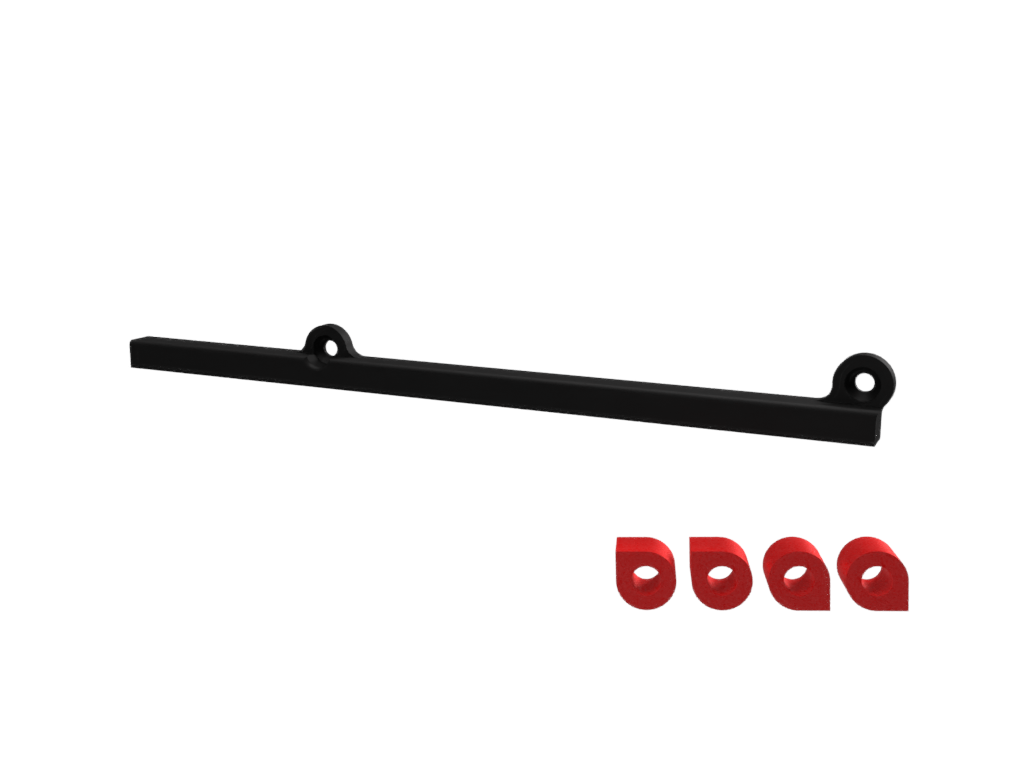

In 2025, we’ve made a major shift — we’ve stopped using photos altogether. We now represent all of our parts using high-resolution 3D product renders. These digitally generated models allow us to show exactly what you’ll get, without the lighting issues, editing, or endless reshoots of traditional photography.

📸 Why We Moved Away from Product Photography

Shooting images of small accessories like violin bridges or bass ramps is incredibly time-consuming. You need perfect lighting, a neutral background, accurate color balance, and lots of editing. Even then, most shots didn’t fully capture the grain, the shape, or the precise contours that matter in lutherie work.

We found ourselves wasting hours per item — only to get 2 or 3 usable images. It was frustrating, inefficient, and honestly didn’t reflect the precision of our products. So we stopped. Instead, we now rely entirely on custom-rendered 3D models built from real-world measurements and specifications.

🖥️ The Benefits of 3D Product Renders

Our new workflow centers on clarity, accuracy, and speed. With 3D product renders, we can show surface textures, tonewood patterns, edge bevels, and profile dimensions far more clearly than with a photo.

- ✅ Consistent lighting across all images

- ✅ Precise proportions and perspective

- ✅ Accurate tonewood colors and textures

- ✅ Faster to produce and update

We now use Blender and other modeling tools to visualize our product designs before they’re even physically cut — which also helps us speed up prototyping and customer-specific modifications.

🎨 Real Examples of Our New Renders

Here are examples of what our 3D product renders look like in use. These images now appear across our store and blog content:

🔗 Internal Links & Helpful Resources

🛠️ Handmade First — Digitally Shown

Just to be clear: we still make everything by hand. The only thing that’s changed is how we show it. These 3D product renders help us better communicate the shape, scale, and quality of what we build.

With more consistency in product visuals, we can also launch new models faster and support our customers more efficiently. We no longer delay releases waiting for the “perfect photo.” We render it right, right away.

📬 Want to Know More?

If you’re curious about how we create our renders, or if you want a custom view of a specific model, contact us. We’re happy to provide rotated views, scale comparisons, and advice on fit and installation.

Thanks for being part of our visual evolution. We’ll keep crafting great accessories — and now we’ll show them with the detail they deserve.